Poor loading dock signage isn’t just an aesthetic miss; it’s a risk multiplier. When high-traffic, high-hazard points in facilities aren’t clearly marked, and risks aren’t communicated with attention-grabbing LED signs, companies can end up paying for them through safety incidents, wasted time, regulatory fines, and poor worker morale.

Discover Signal-Tech's

Full Line of Solutions for

Loading Docks

Loading Docks Deserve More Than Static Signage

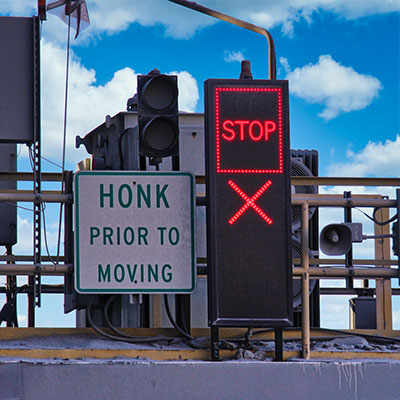

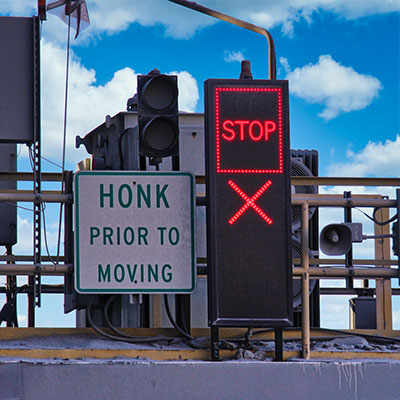

Think of every element found at a loading dock. People, forklifts, heavy vehicles, narrow clearances, and often low lighting all come together in a perfect storm of risk. Every miscommunication at the dock increases the chance of an accident. Traditional static signs simply don’t cut it for safety-critical information where conditions change and visibility matters. LED loading dock signage is a game-changer because it demands attention, increases visibility in low light, and some of these signs can be updated as conditions change. Static signs simply can’t do this.

What are the Costs of Poor Signage?

Safety Incidents and Injuries

Workplace incidents are extraordinarily expensive. National Safety Council (NSC) data from 2023 shows that workplace injuries in the U.S. cost employers nearly $177 billion. Clear, high-visibility safety signage can reduce accidents by up to 20 percent in deskless work settings.

More specifically, missteps at loading docks can lead to:

- Forklifts hitting pedestrians

- Trailer creep (where a truck shifts away from a dock during loading)

- Falls from dock edges

- Vehicle–infrastructure collisions

These aren’t minor “whoopsies.” These types of incidents can result in workers’ comp claims, equipment damage, production downtime, and, in the worst-case scenario, fatalities.

LED loading dock signage is active communication. It catches the eye even when workers are fatigued. This is a huge advantage, especially for workers on night or long shifts, where accident rates are higher.

Regulatory Compliance and Fines

The Occupational Safety and Health Administration (OSHA) standards require clear hazard communication. This includes signs that define hazards that could harm workers or damage property. Standard metal or plastic signs can fade or get obscured, and signs that can’t be seen at night don't meet the functional requirements of these standards. OSHA doesn’t mess around with compliance.

- Fines for missing or improper signage can start at around $16,000 per violation.

- Repeat or willful violations can exceed $160,000 per violation.

Imagine paying a six-figure penalty for something an LED stop/go dock light could prevent.

Read Why

LED Signs are the Unsung Hero of

Creating a Safety Culture

Decreased Productivity and Increased Downtime

Confusion at the dock is costly in terms of safety and time. Think about a driver waiting for the go-ahead signal to pull into or out of a bay, or a forklift operator hesitating because they can’t clearly see whether a trailer is secure. Every minute of uncertainty is a minute not spent moving products. In distribution centers, time is money; wasted minutes mean wasted dollars.

LED loading dock signage instantly communicates status — “STOP,” “GO,” “DO NOT ENTER” — and eliminates guesswork. This especially matters during peak seasons, when every second counts for throughput and labor costs.

The Cost of the Workforce and Its Morale

People matter. Workers who feel unsafe know their employer isn’t doing things to keep them safe. Clear visual cues, especially bright, illuminated messages, signal to employees that management takes safety seriously. Visual signals are processed faster than text alone. This means bright LED signs, which combine a bright, unmistakable visual cue along with a warning message, are far more likely to garner attention than a standard, non-illuminated sign. This reduces stress, increases focus, and most importantly keeps people alive and healthy.

Download

Signal-Tech’s Workplace

Safety Brochure

Why is LED Loading Dock Signage Worth the Investment?

Visibility in All Lighting Conditions

LEDs can shine through nearly any condition Mother Nature throws at them. Glares, direct sunlight, low light, fog, rain, snow, sleet — there are conditions where traditional, unlit signs have the potential to disappear into the background. Whether it’s early morning, late night, or a stormy afternoon, LED loading dock signage communicates clearly and instantly. This is supreme reliability and functionality in almost 100 percent hands-off safety equipment.

A Low Total Cost of Ownership

Painted signs fade. Stickers peel. Conversely, LED signs have lifespans of 50,000 to 100,000 hours, are energy-efficient, and require minimal maintenance. Over time, the total cost — factoring in reduced downtime and fewer replacements — often beats the perceived savings of signage options with a lower initial price tag.

Enhanced Energy Efficiency and Greater Sustainability

LED signs use far less power than traditionally lit signage (e.g., incandescent, fluorescent). This means that while a loading dock, warehouse, or distribution center is improving its visual safety cues, it's also greener and spending less to operate. Interestingly, many LED sign components are also recyclable, aligning with sustainability goals.

Clear Signals at the Dock Aren’t Optional — They’re Essential

Poor signage at the loading dock isn’t just a missed compliance checkpoint; it’s a hidden cost on safety, productivity, and the company’s bottom line. Traditional signs are passive, but illuminated loading dock signage provides an active layer of protection. It’s always visible, it can be dynamic, and it’s a smart choice for enhancing multiple efficiencies.

When safety, efficiency, and compliance are on the line, guesswork has no place at the dock. Contact Signal-Tech’s illuminated dock sign experts to see how LED signage solutions can reduce risk, improve operations, and, over time, pay for themselves.